In the demanding world of industrial mineral processing and powder production, the heart of any grinding mill lies in its rotating assembly. The grinding rollers, which apply immense pressure to crush and pulverize raw materials, are supported by sophisticated bearing systems and protected by robust seals. The performance, reliability, and longevity of the entire grinding operation hinge on the engineering excellence of these critical components. This article provides a comprehensive examination of grinding roller bearings and seals, exploring their functions, challenges, and the technological advancements that ensure optimal performance in harsh operating environments.

Bearings in grinding mills are subjected to some of the most severe conditions in industrial machinery. They must support extremely heavy loads—both radial from the weight of the rollers and thrust from the grinding forces—while operating at elevated temperatures and in an environment contaminated with abrasive dust.

The primary functions of these bearings include:

Spherical roller bearings are often the preferred choice for these applications due to their self-aligning capability, which compensates for minor misalignments and shaft deflections. Their high load-carrying capacity and robustness make them ideal for the shock loads encountered during mill operation.

While bearings carry the load, seals protect them. In a grinding mill, sealing systems face a constant battle against fine, abrasive particles that can quickly degrade bearing surfaces and lubricants. Effective sealing is not merely an accessory but a fundamental requirement for mill reliability.

Modern mill seals typically employ a multi-stage approach:

The selection of seal materials is critical, requiring resistance to abrasion, high temperatures, and chemical degradation from lubricants. Advanced composite materials and specialized elastomers have significantly extended seal life in these challenging applications.

At Shanghai Zenith Machinery Co., Ltd., our extensive experience in developing ore grinding equipment has led to significant innovations in bearing and seal technology. Our engineers understand that the durability of these components directly impacts mill availability, maintenance costs, and total cost of ownership.

Our design philosophy incorporates:

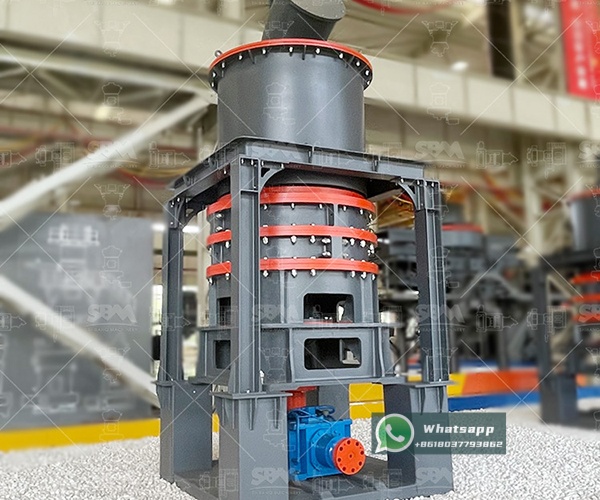

Our LM Vertical Grinding Mill exemplifies our commitment to robust bearing and seal design. By integrating five functions—crushing, grinding, powder selection, drying, and material conveying—into a single machine, the LM series demands exceptional reliability from its rotating components.

The grinding roller assembly in the LM mill features specially engineered spherical roller bearings with enhanced dynamic load ratings. The sealing system incorporates a multi-stage design with labyrinth seals, V-ring seals, and an optional air purge system for the most challenging applications. This comprehensive approach ensures bearing protection even when processing highly abrasive materials.

| Model | Plate diameter (mm) | Capacity (t/h) | Output fineness (μm) | Max feed size (mm) | Main motor (kW) |

|---|---|---|---|---|---|

| LM130K | 1300 | 10-28 | 170-40 | <38 | 200 |

| LM190K | 1900 | 23-68 | 170-40 | <45 | 500 |

| LM280K | 2800 | 50-170 | 170-45 | <50 | 1250 |

For ultrafine powder production, where product contamination is a critical concern and particle sizes can be exceptionally small, our LUM Ultrafine Vertical Mill incorporates even more sophisticated sealing solutions. The bearings in the LUM series are protected by a proprietary sealing system that maintains integrity even with sub-micron particles.

Key features include:

| Model | Main machine power (kW) | Capacity (t/h) | Size distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2.0-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

Proper maintenance is crucial for maximizing the service life of bearings and seals in grinding applications. Key practices include:

The grinding roller bearings and seals in industrial mills represent a remarkable fusion of mechanical engineering, materials science, and practical application knowledge. These components, though often overlooked, are fundamental to mill performance, efficiency, and reliability. At Shanghai Zenith Machinery, our continuous research and development in this area reflects our commitment to providing grinding solutions that deliver not only superior performance but also exceptional durability and low total cost of ownership.

Through advanced design, careful material selection, and integrated sealing systems, modern grinding mills can achieve unprecedented levels of reliability even in the most demanding applications. As grinding technology continues to evolve, bearing and seal innovations will remain at the forefront, enabling more efficient, reliable, and sustainable mineral processing operations worldwide.