Bentonite, a highly absorbent clay composed mainly of montmorillonite, is extensively used in various industrial and environmental applications. One of its most significant uses is in water treatment, where it functions as a purifying agent and flocculant to remove heavy metals and organic impurities. As environmental regulations become increasingly stringent in Canada, there is growing demand for efficient grinding technologies that can process bentonite into fine powders suitable for water treatment applications.

In this context, Shanghai Zenith Machinery Co., Ltd., a renowned manufacturer of industrial grinding mills, offers advanced solutions for bentonite processing. With decades of experience in R&D, production, and innovation, the company provides a comprehensive range of grinding mills customized to meet the demands of Canadian industries. This article explores how bentonite grinding mills—especially those with capacities of 5–10 TPH—can enhance the water treatment sector in Canada, and highlights two of the company’s most efficient models.

Bentonite plays a vital role in the water treatment industry due to its unique chemical and physical properties. When dispersed in water, bentonite particles swell, increase in volume, and create a network capable of adsorbing impurities. Its high surface area and negative charge enable it to attract positively charged ions, such as heavy metals (lead, cadmium, and mercury), while simultaneously absorbing organic pollutants.

In Canadian industrial facilities and municipal systems, bentonite is widely employed to purify wastewater streams and improve effluent quality before discharge into natural water bodies. However, to ensure high efficiency and uniform performance, the raw bentonite must be ground to an appropriate fineness. This is where professional milling technology becomes indispensable.

The efficiency of bentonite in water treatment largely depends on its particle size distribution and surface area. Coarsely ground bentonite typically shows limited adsorption capacity, whereas ultrafine bentonite exhibits greater reactivity, dispersion, and flocculation ability. In general, water treatment-grade bentonite requires fineness levels below 45 microns (with some applications demanding even finer powders).

To achieve such quality, specialized grinding mills are required. Shanghai Zenith Machinery Co., Ltd. offers various models that combine advanced grinding mechanisms, energy efficiency, and precise control systems—ensuring stable operation and consistent product quality.

Canada’s environmental industry faces rigorous performance and ecological standards. As a result, choosing the right grinding mill for bentonite processing is critical. For medium-scale production lines requiring capacities between 5 and 10 tons per hour (TPH), mills must strike a balance between output, energy consumption, and product fineness.

Below are two recommended models from Shanghai Zenith Machinery Co., Ltd., both of which are capable of meeting the demands of bentonite powder production for water treatment applications in Canada.

The MTW Trapezium Grinding Mill series represents Zenith’s latest generation of grinding equipment. Designed with international technology standards, it is widely applicable for processing non-metallic minerals such as bentonite, limestone, gypsum, and kaolin. Its MTW110 model offers a throughput ideally suited for the 5–10 TPH range, making it one of the best options for small to mid-scale water treatment facilities.

| Model | Max. Feed Size (mm) | Final Size (mm) | Capacity (t/h) | Main Motor (kW) | Fan Motor (kW) |

|---|---|---|---|---|---|

| MTW110Z | <30 | 1.6–0.045 | 3–10 | 55 | 55 |

Key advantages of this model include:

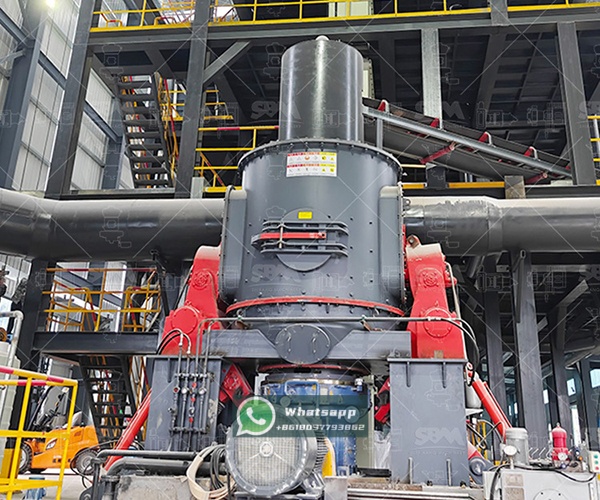

The LM Vertical Grinding Mill series by Zenith integrates several functions—crushing, grinding, drying, classification, and conveying—into one compact machine. It is especially efficient when dealing with bentonite’s sticky and moisture-sensitive properties.

With a typical output of 10–28 TPH and advanced control technologies, the LM130K model provides flexibility to operate within the target 5–10 TPH range. Its vertical structure minimizes floor space, making it suitable for both retrofit projects and new installations in Canadian treatment plants.

| Model | Plate Diameter (mm) | Capacity (t/h) | Output Fineness (μm) | Max Feed Size (mm) | Main Motor (kW) |

|---|---|---|---|---|---|

| LM130K | 1300 | 10–28 | 170–40 | <38 | 200 |

Main benefits of the LM130K Vertical Mill:

In a case study from a Canadian environmental services provider, a 5–10 TPH bentonite grinding system was integrated into a municipal wastewater purification project. The goal was to produce fine bentonite powder suitable for removing contaminants and heavy metal ions from local industrial effluent.

The facility installed an MTW110Z Trapezium Mill, which continuously processed raw bentonite into sub-45 micron powder. The efficiency of pollutant removal increased by over 20%, and treatment costs decreased by approximately 15% compared to previously used imported adsorbents. This demonstrated the tangible advantages of adopting optimized grinding technology from Shanghai Zenith Machinery Co., Ltd.

In another industrial wastewater site, the LM130K Vertical Mill was deployed to provide on-site production capability. Its integrated system not only minimized operational downtime but also permitted direct feeding of produced slurry into the treatment tanks. This streamlined workflow resulted in both higher environmental compliance and operational convenience.

For optimum bentonite grinding results, engineers and plant managers should consider the following key factors when designing or upgrading their systems:

Shanghai Zenith Machinery Co., Ltd. stands as a technological leader in the grinding industry. Based in China, the company has established itself as a trusted supplier of ore and mineral grinding equipment worldwide. In the context of bentonite grinding for water treatment applications, Zenith delivers several key advantages:

Bentonite grinding is a cornerstone process in modern water treatment technologies, enabling cost-effective and sustainable purification of industrial and municipal wastewaters. For Canadian businesses focused on ecological compliance and operational efficiency, customized grinding systems from Shanghai Zenith Machinery Co., Ltd.—such as the MTW110Z Trapezium Mill and the LM130K Vertical Mill—offer ideal performance for 5–10 TPH production capacities.

With their world-class engineering, energy efficiency, and environmentally friendly design, these mills are not merely industrial machines; they are vital components of a greener, more sustainable Canadian water treatment future.