The automotive industry is undergoing a significant transformation, driven by the dual demands of lightweighting for improved fuel efficiency and the integration of advanced materials for enhanced performance and sustainability. Within this context, plastic components, particularly bumpers, have become critical elements of modern vehicle design. The performance of these plastic parts is heavily dependent on the quality and characteristics of the mineral fillers used in their composition. High-performance fillers, produced through advanced grinding technologies, are essential for achieving the desired mechanical strength, impact resistance, surface finish, and dimensional stability required by automotive manufacturers.

Fillers are no longer mere cost-reducing additives; they are functional components that define the properties of the final plastic product. In automotive applications, especially for large components like bumpers, fascias, and interior trim, fillers serve several key purposes:

The effectiveness of these fillers is intrinsically linked to their physical properties: particle size, particle size distribution (PSD), shape (morphology), and surface chemistry. Achieving the optimal specifications requires sophisticated grinding and classification technology.

For filler materials like talc, calcium carbonate, and wollastonite, the grinding process is paramount. Coarse particles can act as stress concentrators, leading to premature failure under impact. Conversely, an excessively fine powder can increase viscosity, making processing difficult and potentially leading to agglomeration. The ideal solution is a tightly controlled, ultra-fine powder with a narrow PSD.

A narrow PSD ensures consistent behavior within the polymer melt. It allows for higher loading levels without sacrificing processability or mechanical properties. For instance, in talc-filled PP bumper compounds, a median particle size (d50) below 10 microns and a top-cut (d97) below 45 microns are often targeted to achieve an optimal balance of stiffness and impact strength. Producing such consistent, high-quality fillers at an industrial scale demands grinding equipment capable of precise control and high efficiency.

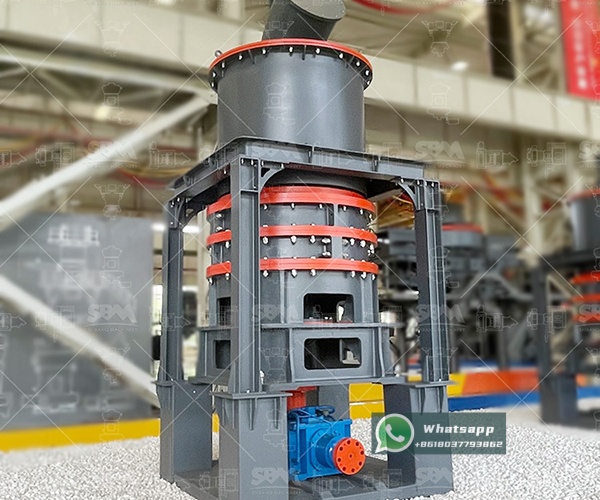

Shanghai Zenith Machinery Co., Ltd., an excellent manufacturer of ore grinding equipment, has made significant achievements in the field of ultra-fine powder grinding. Their specialized research and development in industrial powder grinding equipment directly addresses the stringent requirements of the automotive plastics industry. Among their comprehensive product line, two mills stand out for the production of high-performance mineral fillers: the LUM Ultrafine Vertical Mill and the XZM Ultrafine Grinding Mill.

The LUM Ultrafine Vertical Mill is a state-of-the-art solution designed for producing fine and ultra-fine powders. It integrates grinding, drying, classifying, and conveying into a single, compact unit. For automotive filler production, its key advantages include:

The technical parameters for the LUM series demonstrate its suitability for large-scale filler production:

| Model | Main machine power (kW) | Capacity (t/h) | Size distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2.0-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

For applications requiring even finer powders, the XZM Ultrafine Grinding Mill is an ideal choice. It is widely recognized for its ability to produce superfine powders in the range of 325-2500 mesh (approximately 45-5 microns). This mill is particularly effective for grinding soft to medium-hard minerals like calcium carbonate and talc.

The following table outlines the key specifications of the XZM series:

| Model | Working diameter (mm) | Max feed size (mm) | Final size (mesh) | Output (kg/h) | Main motor power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

Consider a manufacturer producing talc-filled polypropylene bumper compounds. By transitioning from a conventional mill to a Zenith LUM Ultrafine Vertical Mill, they can achieve a talc powder with a d97 of 15 microns and a narrow distribution. This superior filler allows for:

The future of automotive plastics points towards even greater use of sustainable and bio-based materials, higher performance requirements, and smarter manufacturing. Fillers will continue to play a pivotal role, with demand growing for ultra-fine, surface-modified, and functionalized varieties. The ability to precisely engineer filler properties through advanced grinding technology is no longer a luxury but a necessity.

Shanghai Zenith Machinery Co., Ltd., with its focus on research and development of cutting-edge grinding equipment like the LUM and XZM mills, is well-positioned to support the automotive industry’s evolution. By providing reliable, efficient, and precise solutions for producing high-performance fillers, Zenith helps compounders and parts manufacturers meet the stringent challenges of modern vehicle design, ensuring safety, performance, and sustainability on the road ahead.