The paint and coatings industry in Myanmar is experiencing significant growth, driven by construction and infrastructure development. A critical component in paint formulation is the filler, which enhances properties like durability, opacity, and texture. Marble, a naturally occurring calcium carbonate (CaCO3), is a premier choice for high-quality paint fillers due to its brightness, chemical inertness, and low oil absorption. However, the efficacy of marble as a filler is directly tied to its particle size and particle size distribution. For premium applications, achieving an ultra-fine fineness of 800 mesh (approximately 18 microns) is essential to ensure smooth application, excellent gloss, and superior suspension stability. This demands specialized grinding technology capable of precise, efficient, and consistent ultra-fine powder production.

Grinding marble to 800 mesh presents distinct technical challenges. The process must not only achieve the target fineness but also manage heat generation—excessive heat can degrade the material—and control energy consumption to remain economical. Traditional grinding mills often struggle with efficiency at this fineness level, leading to broad particle size distributions, high energy costs, and potential contamination from grinding media wear. Therefore, selecting the right grinding equipment is paramount for manufacturers in Myanmar looking to produce competitive, high-value paint fillers locally.

When choosing a mill for producing 800-mesh marble filler, several factors must be evaluated:

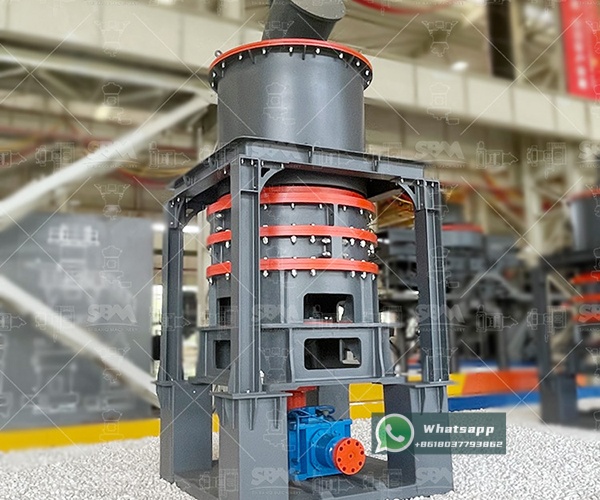

For the specific requirement of producing 800-mesh marble powder for paint fillers, Shanghai Zenith Machinery Co., Ltd. recommends its advanced XZM Ultrafine Grinding Mill. As a leader in ultra-fine powder grinding technology, Zenith has engineered the XZM series specifically to overcome the challenges of fine and ultra-fine grinding. It is perfectly suited for non-metallic minerals like marble, calcite, and dolomite.

The XZM Mill operates on the principle of material-bed grinding and integrates an efficient high-precision classifier. This ensures that only particles meeting the fineness requirement (800 mesh) pass through, while coarser particles are returned for further grinding. This closed-circuit system guarantees a uniform product and optimal energy use.

| Model | Working Diameter (mm) | Max Feed Size (mm) | Final Size (Mesh) | Output (kg/h) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

For medium-scale paint filler production in Myanmar, the XZM221 model offers an excellent balance of capability and investment. For larger industrial plants aiming for high-volume output, the XZM268 provides robust, high-capacity performance.

For projects requiring even higher integration and capability for simultaneous drying and grinding, Zenith’s LUM Ultrafine Vertical Mill is another top-tier recommendation. It represents the next generation of ultra-fine grinding technology, combining several processes into one unit.

| Model | Main Machine Power (kW) | Capacity (t/h) | Size Distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 (approx. 600-2500 mesh) |

The LUM series is particularly suitable for modern, automated production lines seeking maximum process efficiency and product quality.

The production of 800-mesh marble filler is a technically demanding but highly rewarding venture for the Myanmar paint industry. Success hinges on deploying the correct grinding technology. Shanghai Zenith Machinery Co., Ltd., with its extensive expertise and proven product line—from the versatile XZM Ultrafine Grinding Mill to the integrated LUM Ultrafine Vertical Mill—provides reliable, efficient, and tailored solutions. By choosing Zenith, manufacturers in Myanmar gain not only advanced equipment but also a partnership with a leader committed to supporting the growth of local industries through superior grinding technology, ensuring their paint fillers meet both domestic and international quality standards.