Phosphate rock plays a critical role as a fundamental raw material in various industries, including agriculture, chemicals, and ceramics. In Zambia, where the mining sector continues to grow, the demand for highly efficient and precise grinding technology is becoming increasingly important. Especially in the ceramic industry, ultra-fine grinding capability, such as achieving particle sizes of 1000 mesh, is essential for ensuring the quality and homogeneity of the final products. To meet this demand, advanced grinding mills from Shanghai Zenith Machinery Co., Ltd. provide an efficient, energy-saving, and reliable solution for phosphate rock processing.

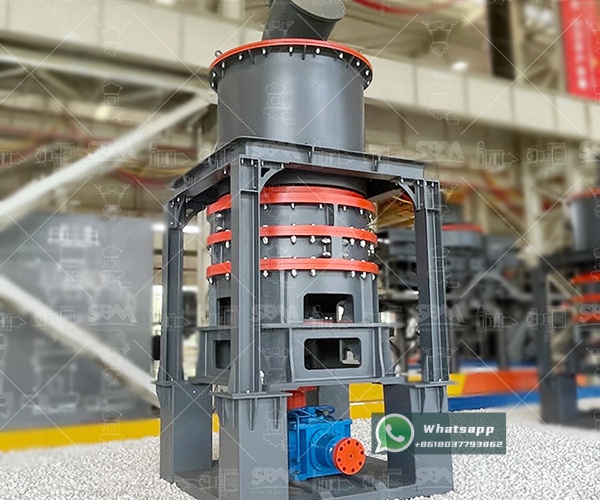

Shanghai Zenith Machinery Co., Ltd., established as a leading manufacturer of ore grinding equipment, has consistently contributed to the development of high-performance grinding systems. The company’s comprehensive product line covers a variety of industrial grinding mills including the MTW Trapezium Grinding Mill, Ball Mill, MTM Medium-Speed Grinding Mill, Raymond Mill, LM Vertical Grinding Mill, LUM Ultrafine Vertical Mill, XZM Ultrafine Grinding Mill, and Hammer Mill. Each of these mills offers specific advantages for processing materials like phosphate rock, ensuring efficient results even in demanding conditions.

Ceramic production demands extremely fine and uniform raw material particles. When phosphate rock is used as part of the ceramic formulation, it improves thermal stability and contributes to the structural integrity of the final product. To achieve a consistent material at 1000 mesh fineness, the grinding process must ensure particle size control, minimized contamination, and efficient classification.

In Zambia, local phosphate deposits offer great potential for ceramic applications. However, these materials typically require advanced processing to meet industrial standards. The selection of an appropriate grinding mill is therefore crucial, as it directly affects production efficiency, operating costs, and the quality of output materials.

The phosphate rock found in Zambia possesses certain mineralogical characteristics that make it moderately hard and slightly abrasive. Traditional grinding systems often encounter issues such as high energy consumption, reduced wear resistance of components, and insufficient control over ultrafine particle formation. Furthermore, the environmental impact of dust emissions and the need for sustainable water management in wet grinding processes necessitate the adoption of advanced and integrated grinding solutions.

To overcome these challenges, ceramic producers in Zambia can greatly benefit from the advanced technology provided by Shanghai Zenith Machinery Co., Ltd. Their modern grinding systems, such as the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill, are specifically designed for fine and super-fine powder generation, ensuring consistent product fineness and energy-efficient performance.

For achieving 1000 mesh fineness in phosphate rock grinding, two of Zenith’s state-of-the-art machines are highly recommended: the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill. Both models feature precision grinding and classification technology, making them ideal for ceramic-grade phosphate powder production.

The XZM Ultrafine Grinding Mill provides a highly efficient and stable platform for producing superfine powders. Designed with advanced internal classification and optimized grinding geometry, it can handle materials with a Mohs hardness below 6 and a moisture level below 6%. The built-in high-frequency inverter ensures flexible speed control, allowing the mill to adapt to various production conditions. For phosphate rock grinding in Zambia, this mill achieves an optimal balance between energy consumption, throughput, and particle uniformity.

| Model | Working diameter (mm) | Max feed size (mm) | Final size (mesh) | Output (kg/h) | Main motor power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

By selecting the appropriate XZM model, producers can customize their output size to precisely 1000 mesh, offering perfect suitability for ceramic raw materials preparation. Additionally, the modular design facilitates easy maintenance, while the dust collector and silencer ensure an environmentally friendly grinding process.

The LUM Ultrafine Vertical Mill represents Zenith’s pinnacle of vertical grinding innovation, integrating grinding, drying, classifying, and conveying. Thanks to its advanced multi-rotor classifier and adjustable air flow system, it achieves particle size distribution control at a range of 5–30 μm. The distinctive design enables stable operation with low vibration, making it particularly suitable for large-scale continuous phosphate rock processing plants in Zambia’s ceramic industry.

| Model | Main machine power (kW) | Capacity (t/h) | Size distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220–250 | 1.6–11.5 | 5–30 |

| LUM1632 | 280–315 | 2.0–13.5 | 5–30 |

| LUM1836 | 355–400 | 2.3–15 | 5–30 |

With its unique pressure adjustment and intelligent control system, the LUM Mill guarantees consistent fine powder output while minimizing energy consumption. The built-in classifier allows precision control over 1000 mesh fineness, enhancing the efficiency of ceramic material preparation lines.

Shanghai Zenith Machinery Co., Ltd. distinguishes itself through an emphasis on high-precision design and durable system construction. The major benefits of adopting Zenith equipment for phosphate rock grinding in Zambia include:

With Zambia’s mining and manufacturing sectors expanding, the ceramic industry has strong prospects. The local availability of mineral resources, including phosphate rock, clay, and feldspar, provides ideal conditions for developing domestic porcelain, tile, and sanitary ware production. Advanced grinding technologies, such as those from Shanghai Zenith Machinery Co., Ltd., can significantly reduce dependency on imported raw powders and minimize production costs.

By utilizing XZM and LUM Mills, Zambian manufacturers can establish vertically integrated production lines that maintain consistent feed size and high-quality output. The improved material characteristics achieved through ultrafine grinding ensure smoother sintering behavior, enhanced mechanical strength, and more uniform coloration in ceramic bodies.

In conclusion, as Zambia’s ceramic material industry seeks higher quality and efficiency, choosing the right grinding system becomes a key strategic decision. The Phosphate Rock Grinding Mill for Ceramic Materials in Zambia (1000 mesh) solution provided by Shanghai Zenith Machinery Co., Ltd. offers unmatched advantages in performance, stability, and operational economy. Through models such as the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill, producers can achieve superior product quality, sustainable operation, and a significant return on investment.

With its global experience and comprehensive technical support, Zenith continues to empower industries around the world, helping partners in Zambia and beyond to adopt cutting-edge powder processing technology for a sustainable and profitable future.