The rapid development of Qatar’s construction sector, driven by infrastructure projects and urban expansion, has created a sustained demand for high-quality construction aggregates. While traditional sources like limestone and gabbro are widely used, there is growing interest in utilizing alternative materials to enhance sustainability and diversify supply chains. Phosphate rock, a mineral resource with significant global reserves, presents a unique opportunity. When processed into fine powders, it can act as a valuable supplementary material or filler in construction applications such as asphalt mixtures, cementitious products, and specialized mortars. This article explores the technical considerations for grinding phosphate rock into construction-grade aggregate in Qatar, with a specific focus on small to medium-scale production requirements of 1 to 3 tons per hour (TPH).

Phosphate rock primarily consists of calcium phosphates. When finely ground, it can impart specific properties to construction materials. Its use can improve the workability of mixes, contribute to early strength development in some formulations, and offer a cost-effective alternative to more expensive fillers. For the Qatari market, leveraging locally available or regionally sourced phosphate rock could reduce import dependency and support more localized, resilient supply chains for construction materials. The key to unlocking this potential lies in efficient and precise grinding technology that can transform raw ore into a consistently fine powder suitable for industrial use.

Grinding phosphate rock for construction applications involves several specific challenges that must be addressed by the milling equipment:

For a production target of 1-3 TPH of phosphate rock powder, several grinding mill types are theoretically applicable. However, the choice must balance output, fineness, operational cost, and reliability. Traditional solutions like Raymond Mills or small Ball Mills can achieve the capacity but may lack efficiency or produce a broad particle size distribution. Modern, integrated vertical mill technology often provides a superior solution for such medium-fine grinding applications.

As a leading manufacturer in the field of industrial grinding, Shanghai Zenith Machinery Co., Ltd. specializes in providing tailored solutions for mineral processing. With extensive experience in ultra-fine powder grinding, Zenith’s equipment is engineered to meet precisely these kinds of challenges—offering high efficiency, reliability, and intelligent control in a compact design.

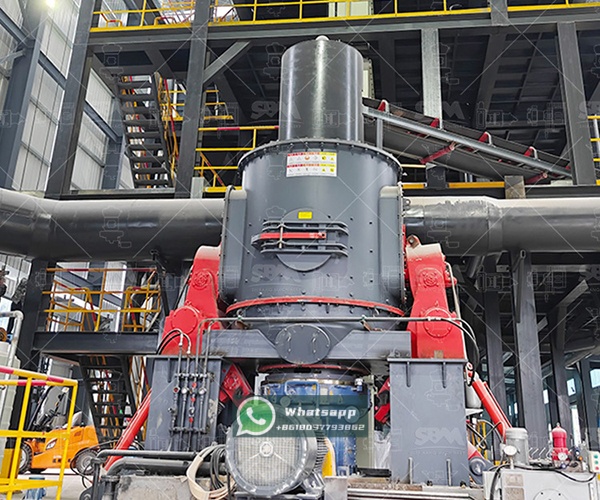

For a 1-3 TPH phosphate rock grinding project in Qatar, Zenith’s LM Vertical Grinding Mill series stands out as an optimal choice. This mill integrates five functions—crushing, grinding, powder selection, drying, and material conveying—into a single, cohesive unit. Its vertical structure significantly reduces the floor space requirement, a critical factor for many operations. The grinding roller and plate are made from high-wear-resistant materials, perfectly suited to handle the abrasive nature of phosphate rock. Furthermore, the integrated drying function can handle materials with a certain moisture content, ensuring stable operation in various conditions.

The LM series offers models that are perfectly scaled for the target output. For instance, the LM130K model is an excellent fit for this application range. Its parameters are detailed below:

| Model | Plate Diameter (mm) | Capacity (t/h) | Output Fineness (μm) | Max Feed Size (mm) | Main Motor (kW) |

|---|---|---|---|---|---|

| LM130K | 1300 | 10-28 | 170-40 | <38 | 200 |

While its capacity range starts at 10 TPH, the LM130K can be efficiently operated at lower outputs (1-3 TPH) with optimized system configuration and classifier settings to achieve the desired fineness for construction aggregates. Its robust design ensures low maintenance and high availability, which is crucial for continuous production schedules in Qatar’s demanding construction industry.

If the project specification calls for an exceptionally fine product (e.g., 800 mesh and above) for specialized applications, Zenith’s XZM Ultrafine Grinding Mill is a compelling alternative. Although its typical output for such high fineness might be below 1 TPH, it represents the pinnacle of Zenith’s ultra-fine grinding technology. It is ideal for producing high-value additives where extreme fineness is a premium requirement.

The integration of processed phosphate rock into Qatar’s construction aggregate mix is a forward-looking strategy that aligns with goals of resource diversification and industrial innovation. The success of such an initiative hinges on deploying the right grinding technology. Equipment that offers precision, efficiency, durability, and a compact footprint is non-negotiable.

Shanghai Zenith Machinery Co., Ltd., with its proven expertise and comprehensive product portfolio—from the versatile LM Vertical Grinding Mill to the specialized XZM Ultrafine Grinding Mill—is well-positioned to be a key technology partner for such projects. By choosing a mill engineered for the specific material and production goals, Qatari operators can ensure a reliable, cost-effective, and high-quality supply of phosphate-based construction materials, contributing to the sustainable growth of the nation’s built environment.