Algeria, endowed with significant mineral resources, holds a strategic position in North Africa’s industrial landscape. Among its key resources is phosphate rock, a crucial raw material not only for fertilizers but also as an essential flux in metallurgical processes. In steelmaking and non-ferrous metal production, a finely ground phosphate rock flux promotes slag formation, removes impurities, and improves the overall efficiency and quality of the melt. Achieving the optimal particle size—specifically a consistent 150 mesh (approximately 100 microns)—is paramount for its reactivity and performance in the furnace. This article delves into the technical requirements for grinding phosphate rock for metallurgical flux in Algeria and explores the advanced milling solutions that can drive this critical operation.

In metallurgy, a flux is a substance added to the charge to lower the melting point of the gangue and facilitate the removal of impurities as slag. Phosphate rock, primarily composed of apatite, serves this purpose effectively. When ground to 150 mesh, it offers a high surface area-to-volume ratio, ensuring rapid dissolution and homogeneous mixing within the molten metal. This fine particle size is critical for:

For Algerian processing plants, consistently meeting this 150-mesh specification while maintaining throughput and operational cost-effectiveness is the central challenge.

Phosphate rock presents specific grinding challenges that not all milling equipment can handle efficiently. Its hardness can vary (Mohs hardness ~5), and it often contains moisture and abrasive impurities. Key challenges include:

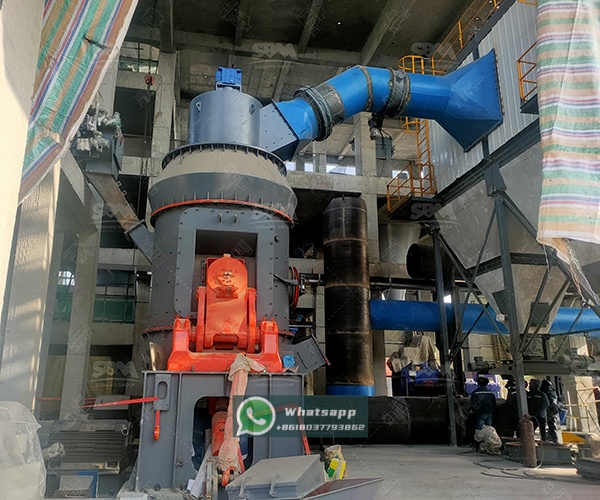

Selecting the right grinding mill is the cornerstone of a successful phosphate rock flux preparation plant. The ideal solution must offer durability, precision, energy efficiency, and system intelligence. As a leader in comminution technology, Shanghai Zenith Machinery Co., Ltd. specializes in the research, development, and production of industrial powder grinding equipment perfectly suited for this application. Among our comprehensive portfolio, two solutions stand out for processing phosphate rock to 150 mesh: the MTW Trapezium Grinding Mill and the LM Vertical Grinding Mill.

The MTW Trapezium Grinding Mill is engineered with multiple patents and represents a generational leap in grinding technology. Its curved air duct, internal efficient powder separator, and wear-resistant materials make it an excellent choice for processing moderately hard minerals like phosphate rock. For a 150-mesh product, its grinding efficiency and classification system are particularly advantageous.

| Model | Max. Feed Size (mm) | Final Size (mm) | Capacity (t/h) | Main Motor (kW) |

|---|---|---|---|---|

| MTW138Z | <35 | 1.6-0.045 (approx. 10-325 mesh) | 6-17 | 90 |

| MTW175G | <40 | 1.6-0.045 | 9.5-25 | 160 |

| MTW215G | <50 | 1.6-0.045 | 15-45 | 280 |

Note: The 150-mesh target (0.106 mm) is well within the adjustable range of the MTW series. The integrated classifier ensures precise particle size control.

For an Algerian plant with a production target in the medium-to-high capacity range, the MTW175G or MTW215G model would be ideal, offering robust construction to handle abrasive feed, high output, and superior energy efficiency per ton of product.

For operations prioritizing a smaller footprint, integrated drying, and exceptional overall system efficiency, the LM Vertical Grinding Mill is the premier choice. It integrates crushing, grinding, powder selection, drying, and conveying into a single unit. This is particularly beneficial if the Algerian phosphate rock has variable moisture content. Its grinding principle, where rollers directly crush materials on a rotating table, is highly efficient and results in lower energy consumption compared to traditional ball mills.

| Model | Plate Diameter (mm) | Capacity (t/h) | Output Fineness (μm) | Main Motor (kW) |

|---|---|---|---|---|

| LM130K | 1300 | 10-28 | 170-40 (approx. 90-400 mesh) | 200 |

| LM190K | 1900 | 23-68 | 170-40 | 500 |

Note: The LM series can easily and stably achieve the 150-mesh (106 μm) specification. The integrated dryer handles moisture, making the process all-weather reliable.

The LM130K or LM190K model would provide a compact, high-capacity, and energy-optimized solution for large-scale flux production facilities in Algeria, ensuring a dry, consistently fine product ready for the metallurgical process.

The production of high-quality phosphate rock flux at 150 mesh is a technically demanding but highly rewarding endeavor for Algeria’s growing metallurgical industry. Success hinges on partnering with a technology provider that understands both the material science and the operational economics. Shanghai Zenith Machinery Co., Ltd., with its proven expertise in ultra-fine powder grinding and a comprehensive portfolio of advanced mills, is ideally positioned to be that partner.

Whether through the high-precision and efficiency of the MTW Trapezium Grinding Mill or the integrated, space-saving prowess of the LM Vertical Grinding Mill, we offer reliable, cutting-edge solutions tailored to the specific needs of the Algerian market. By investing in the right grinding technology, Algerian enterprises can secure a critical link in their metallurgical supply chain, enhancing product quality, reducing costs, and strengthening their competitive edge on the global stage.