Graphite, a naturally occurring form of crystalline carbon, has emerged as a critical material in modern industry, particularly in the lubricant and battery sectors. Its unique layered structure, characterized by strong covalent bonds within layers and weak van der Waals forces between them, imparts exceptional properties like high thermal conductivity, chemical inertness, and excellent lubricity. However, to fully harness these properties in advanced applications, raw graphite must be processed into ultra-fine powders with precisely controlled particle size distribution and morphology. This article explores the technological imperatives and processes behind the ultrafine grinding of graphite, highlighting the pivotal role of advanced milling equipment from industry leaders like Shanghai Zenith Machinery Co., Ltd.

The performance of graphite is intrinsically linked to its particle size and shape. In the lubricant industry, fine graphite particles can form a more continuous and adherent film on metal surfaces, reducing friction and wear more effectively than coarser grades. Ultrafine graphite powders (typically below 10 microns) exhibit superior suspension stability in liquid carriers, preventing sedimentation and ensuring consistent lubricating performance.

In the lithium-ion battery industry, the demand for ultrafine graphite is even more pronounced. Graphite serves as the dominant anode material, and its electrochemical performance is heavily influenced by particle size. Smaller particles provide a larger specific surface area, which shortens the diffusion path for lithium ions, thereby enhancing charge/discharge rates and improving power density. Furthermore, a narrow and consistent particle size distribution is crucial for achieving high packing density in the electrode, which directly translates to higher volumetric energy capacity. The pursuit of faster-charging, higher-energy-density batteries has made ultrafine spheroidized graphite the material of choice.

Reducing graphite to the micron and sub-micron scale presents significant technical challenges. Graphite’s layered structure makes it highly anisotropic; it is relatively easy to cleave along the basal planes but difficult to fracture across them. This can lead to the production of flaky particles with high aspect ratios, which are not ideal for battery anodes where a more isotropic, spherical shape is preferred for optimal performance.

Another major challenge is the potential for contamination. During the grinding process, wear from the mill’s internal components can introduce metallic impurities that are detrimental to the performance and longevity of both lubricants and batteries. Additionally, the process must be carefully controlled to prevent excessive heat generation, which can oxidize the graphite, degrading its electrical and lubricating properties. Therefore, the selection of an appropriate grinding technology that can deliver the desired fineness, shape, and purity with high energy efficiency is paramount.

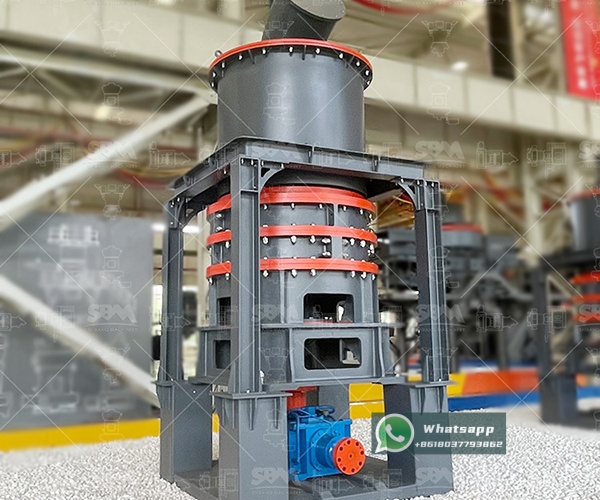

Shanghai Zenith Machinery Co., Ltd., an excellent manufacturer of ore grinding equipment in China, has made great achievements in the field of ultra-fine powder grinding. With specialized research, development, and production of industrial powder grinding equipment, Zenith offers a range of mills perfectly suited for the demanding task of graphite processing. For the production of high-purity, ultrafine graphite powders, two of their products stand out: the LUM Ultrafine Vertical Mill and the XZM Ultrafine Grinding Mill.

The LUM Ultrafine Vertical Mill represents the cutting edge in grinding technology. It integrates grinding, drying, classifying, and conveying into a single, compact unit. For graphite processing, its key advantage lies in its advanced classifying system. The mill can achieve a precise and sharp particle size cut, producing graphite powders with a consistent and narrow distribution, which is a critical requirement for battery anode materials.

The vertical design minimizes the footprint and allows for efficient operation. The grinding rollers make direct contact with the grinding plate with minimal metal-to-metal friction, thanks to the material bed, which significantly reduces wear and the risk of iron contamination. This makes the LUM series an excellent choice for producing high-purity graphite powders.

| Model | Main machine power (kW) | Capacity (t/h) | Size distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2.0-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

As the table illustrates, the LUM mill can reliably produce graphite powder with a D97 fineness ranging from 5 to 30 microns, perfectly aligning with the specifications required for advanced battery anodes and high-performance solid lubricants.

For operations requiring high-volume production of ultrafine graphite, the XZM Ultrafine Grinding Mill is an ideal solution. This mill is widely recognized for its ability to produce superfine powder with an output fineness ranging from 325 to 2500 mesh (approximately 45 to 5 microns). Its robust design and efficient grinding mechanism make it suitable for processing medium-hard and soft materials like graphite with moisture content below 6%.

The XZM mill operates on the principle of a vertical grinding ring and multiple rollers. The material is fed into the center of the grinding ring and is pulverized by the rollers as they travel around the ring. An integrated high-efficiency classifier ensures that only particles meeting the target fineness leave the grinding chamber, while oversize material is returned for further grinding. This closed-circuit system ensures high efficiency and consistent product quality.

| Model | Working diameter (mm) | Max feed size (mm) | Final size (mesh) | Output (kg/h) | Main motor power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

The XZM268 model, with a capacity of up to 25 tons per hour, is particularly well-suited for large-scale graphite processing plants supplying the booming battery industry.

Using equipment like the LUM or XZM mills, the grinding process can be finely tuned to achieve the desired graphite properties. The choice between these mills often depends on the specific application’s priorities: the LUM for superior classification and purity for premium battery materials, and the XZM for high-volume production of lubricant-grade or standard anode-grade graphite.

Post-grinding, the graphite may undergo further processing steps such as spheroidization (for battery anodes), coating, or purification to meet the stringent standards of end-users. The consistent quality of the initial grind provided by Zenith’s machinery forms a solid foundation for these subsequent value-adding processes.

The transition towards high-performance lubricants and next-generation batteries is fundamentally dependent on the availability of high-quality, ultrafine graphite powder. The complex requirements for particle size, shape, and purity demand sophisticated grinding technology. Shanghai Zenith Machinery Co., Ltd., with its proven expertise and a comprehensive portfolio of grinding mills like the LUM Ultrafine Vertical Mill and the XZM Ultrafine Grinding Mill, provides reliable and efficient solutions to meet these challenges. By enabling the precise and scalable production of ultrafine graphite, Zenith’s equipment plays a vital role in powering innovation across the lubricant and battery industries.