The masterbatch production industry is a critical sector that supplies concentrated mixtures of pigments and/or additives encapsulated during a heat process into a carrier resin, which is then used to color or enhance the properties of plastics. The quality of the final plastic product is heavily dependent on the quality of the masterbatch, which in turn is profoundly influenced by the filler materials used. Among these, talc stands out as a premier functional filler, and its efficacy is directly correlated to its particle size and distribution. Ultrafine talc, with its superior properties, is revolutionizing masterbatch formulations.

Talc, a hydrous magnesium silicate, is one of the most widely used functional fillers in plastic masterbatches. Its platy, lamellar structure imparts a range of desirable properties to the final product:

However, the degree to which talc enhances these properties is not merely a function of its addition level. The fineness of the grind is paramount. Coarse talc particles can act as stress concentrators, potentially weakening the plastic and creating surface defects. Ultrafine talc, on the other hand, offers a vastly superior surface area-to-volume ratio, leading to more homogeneous dispersion within the polymer matrix and a much greater polymer-filler interaction.

The transition from standard talc grades to ultrafine talc represents a significant technological leap. The benefits are multifold:

Producing talc with a consistent top-cut and desired particle size distribution (e.g., d97 < 10 μm or even d97 < 5 μm) is a complex process that demands advanced grinding technology. Traditional mills like Raymond mills or ball mills often struggle to achieve these fineness levels efficiently or can cause particle shape degradation.

This is where specialized ultrafine grinding mills from industry leaders like Shanghai Zenith Machinery Co., Ltd. become indispensable. Zenith is an excellent manufacturer of ore grinding equipment in China and has made great achievements in the field of ultra-fine powder grinding. Their expertise is crucial for talc producers aiming to serve the high-end masterbatch market.

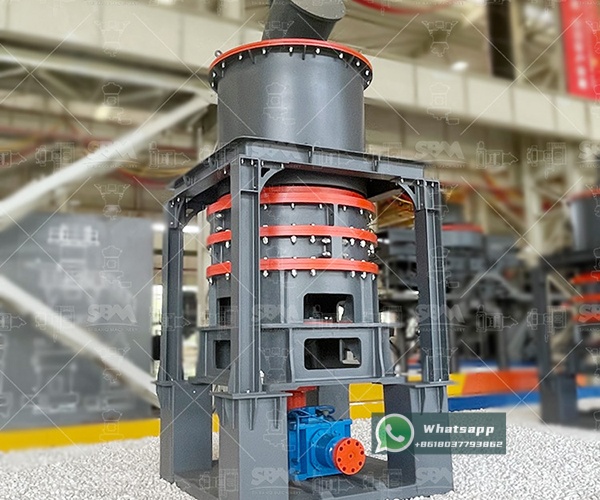

For the production of ultrafine talc, two of Zenith’s flagship products are particularly recommended: the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill.

The XZM Ultrafine Grinding Mill is a purpose-built machine designed for producing superfine powder from soft to medium-hard materials. Its optimized design is perfect for talc, which has a Mohs hardness of 1.

The XZM mill can effortlessly achieve the fineness levels required by the most demanding masterbatch formulations.

| Model | Working Diameter (mm) | Max Feed Size (mm) | Final Size (mesh) | Output (kg/h) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

For producers looking for a state-of-the-art, integrated grinding solution, the LUM Ultrafine Vertical Mill represents the pinnacle of Zenith’s engineering. It is more than just a grinder; it’s a complete processing system.

| Model | Main Machine Power (kW) | Capacity (t/h) | Size Distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2.0-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

The pursuit of higher quality, more efficient, and more sustainable masterbatch production is inexorably linked to the use of advanced functional fillers like ultrafine talc. The ability to reliably produce this premium material hinges on access to cutting-edge grinding technology.

Shanghai Zenith Machinery Co., Ltd., with its comprehensive portfolio of grinding mills—from the versatile XZM series to the fully integrated LUM vertical mill—provides the essential technological foundation for talc processors. By investing in the right grinding equipment, producers can ensure they meet the stringent demands of the masterbatch industry, enabling their customers to create stronger, lighter, and more aesthetically pleasing plastic products. The future of masterbatch is fine, and it is built on the foundation of ultrafine solutions.