Copper reverberatory slag, a byproduct of copper smelting processes, presents both environmental challenges and economic opportunities. With proper processing and grinding technology, this industrial waste can be transformed into valuable materials for construction, cement production, and other applications. Among various grinding technologies available, vertical mill systems have emerged as the most efficient and sustainable solution for processing copper slag.

Copper reverberatory slag typically contains significant amounts of iron, silica, and residual copper compounds. The material exhibits high hardness (Mohs hardness 6-7) and abrasive characteristics, making it challenging to process with conventional grinding equipment. The particle size of raw slag varies widely, from large chunks to fine particles, requiring versatile grinding solutions that can handle this variability while maintaining consistent output quality.

Vertical grinding mills offer several distinct advantages for copper slag processing compared to traditional ball mills or Raymond mills. The integrated design combines multiple processing stages – crushing, grinding, drying, classification, and transportation – into a single compact unit. This integrated approach significantly reduces energy consumption by 30-50% compared to conventional systems while maintaining high throughput capacity.

The vertical orientation of the grinding mechanism allows for more efficient material flow and better control over the grinding process. Gravity assists in material transportation through the mill, reducing the need for additional conveying equipment and minimizing power consumption. Furthermore, the enclosed system design effectively contains dust, meeting stringent environmental regulations for particulate emissions.

Shanghai Zenith Machinery Co., Ltd., as an excellent manufacturer of ore grinding equipment in China, has developed specialized vertical mill solutions specifically designed for challenging materials like copper reverberatory slag. Our extensive research and development in ultra-fine powder grinding technology has resulted in mills that deliver superior performance in slag processing applications.

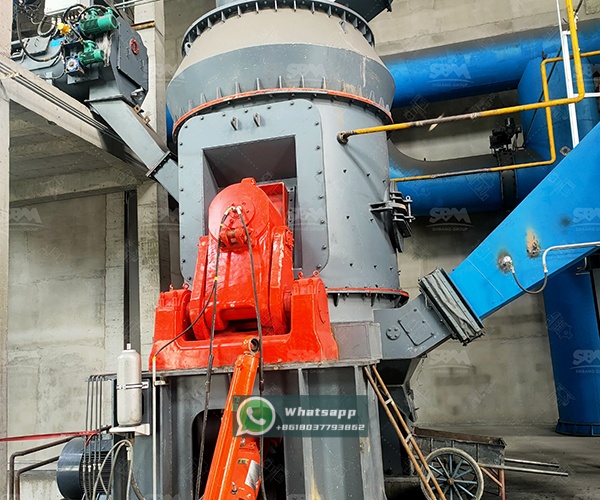

For medium to large-scale copper slag processing operations, we recommend our LM Vertical Grinding Mill series. This equipment integrates five functions—crushing, grinding, powder selection, drying, and material conveying—into a single machine, making it ideal for processing abrasive materials like copper slag.

| Model | Plate diameter (mm) | Capacity (t/h) | Output fineness (μm) | Max feed size (mm) | Main motor (kW) |

|---|---|---|---|---|---|

| LM130K | 1300 | 10-28 | 170-40 | <38 | 200 |

| LM190K | 1900 | 23-68 | 170-40 | <45 | 500 |

| LM280K | 2800 | 50-170 | 170-45 | <50 | 1250 |

The LM Vertical Grinding Mill features a specially designed grinding plate and roller system that withstands the abrasive nature of copper slag. The hydraulic system allows for easy adjustment of grinding pressure, enabling operators to optimize performance based on slag characteristics and desired product fineness. The integrated drying system is particularly beneficial when processing slag with moisture content, eliminating the need for separate drying equipment.

For operations requiring ultra-fine grinding of copper slag for high-value applications such as cement replacement or specialty construction materials, we recommend our LUM Ultrafine Vertical Mill. This advanced mill system produces consistent fine powders with tight particle size distribution, essential for premium applications.

| Model | Main machine power (kW) | Capacity (t/h) | Size distribution D97 (μm) |

|---|---|---|---|

| LUM1525 | 220-250 | 1.6-11.5 | 5-30 |

| LUM1632 | 280-315 | 2.0-13.5 | 5-30 |

| LUM1836 | 355-400 | 2.3-15 | 5-30 |

The LUM Ultrafine Vertical Mill incorporates advanced classification technology that ensures precise control over final product fineness. The intelligent control system automatically adjusts operating parameters to maintain consistent product quality despite variations in feed material characteristics. This capability is particularly valuable when processing copper slag, which often exhibits batch-to-batch variability.

Successful implementation of vertical mill technology for copper slag requires careful consideration of several operational factors. The abrasive nature of slag necessitates the use of wear-resistant materials in critical components. Shanghai Zenith’s vertical mills incorporate specialized wear protection in high-wear areas, significantly extending service life and reducing maintenance requirements.

Moisture content in the feed material must be carefully controlled, typically below 6-8% for optimal grinding efficiency. Our vertical mills include integrated drying systems that can handle moderately moist materials, but pre-drying may be necessary for slag with higher moisture content. The grinding temperature should be maintained within optimal ranges to prevent material degradation and ensure consistent product quality.

The adoption of vertical mill technology for copper slag processing delivers significant economic and environmental benefits. The high grinding efficiency translates to lower energy consumption per ton of processed material, reducing operational costs. The compact footprint of vertical mills minimizes space requirements, an important consideration for facilities with limited available area.

From an environmental perspective, vertical mills offer superior dust containment compared to open grinding systems. The enclosed design, combined with efficient baghouse filtration systems, ensures compliance with air quality regulations. Additionally, the transformation of copper slag from waste to valuable product contributes to circular economy principles, reducing the environmental impact of copper production.

A major copper smelting facility in South America recently implemented Shanghai Zenith’s LM190K Vertical Grinding Mill for processing their reverberatory slag. The installation has demonstrated remarkable results, processing 45-50 tons per hour of copper slag to a fineness of 250-300 Blaine. Energy consumption has been reduced by approximately 40% compared to their previous ball mill system, while product consistency has significantly improved.

The ground slag is now being sold as a premium cement replacement material, generating additional revenue streams for the facility. The payback period for the equipment investment was less than 18 months, considering both operational savings and new revenue generation.

The future of copper slag processing continues to evolve, with ongoing research focusing on even more efficient grinding technologies and new applications for ground slag products. Shanghai Zenith is at the forefront of these developments, continuously improving our vertical mill designs to enhance efficiency, reliability, and versatility.

Emerging applications for ultra-fine copper slag powders include use as functional fillers in polymers, coatings, and other specialty materials. These high-value applications require precise control over particle size distribution and surface characteristics, driving further innovation in grinding and classification technology.

Vertical mill technology represents the most advanced and efficient solution for grinding copper reverberatory slag. Shanghai Zenith’s LM Vertical Grinding Mill and LUM Ultrafine Vertical Mill offer robust, high-performance solutions tailored to the specific challenges of slag processing. With their integrated design, energy efficiency, and superior product quality control, these mills enable copper producers to transform waste materials into valuable products while reducing environmental impact and operating costs.

As sustainability becomes increasingly important in the metals industry, the adoption of advanced grinding technologies for byproduct valorization will continue to grow. Shanghai Zenith remains committed to developing innovative grinding solutions that support our customers’ operational and sustainability objectives.