Australia has long been a major hub for infrastructure development, with a strong demand for high-quality construction aggregates. Among the various materials used in construction, granite aggregates hold a unique position due to their exceptional hardness, durability, and resistance to weathering. However, processing granite into the required fine aggregates or powders requires advanced grinding technologies. In this context, Shanghai Zenith Machinery Co., Ltd., a leading Chinese manufacturer of ore grinding equipment, plays a key role in supplying high-performing grinding solutions that meet the specific needs of the Australian construction aggregate market.

Granite is a coarse-grained igneous rock composed primarily of feldspar, quartz, and mica. It has excellent mechanical properties, including high compressive strength and abrasion resistance, making it one of the most desirable materials for construction aggregate production. In Australia, processed granite aggregates are widely used in asphalt mixtures, concrete production, and road building.

However, the processing of granite into 10–20 TPH (tons per hour) construction aggregates requires equipment that can handle tough, abrasive materials while maintaining fine particle size control and energy efficiency. Traditional mills often struggle with wear and inconsistent output quality. Therefore, using advanced grinding mills capable of crushing, grinding, classifying, and drying in a single integrated system is crucial to achieving both efficiency and cost-effectiveness.

Granite grinding mills transform raw granite boulders into various aggregate sizes suitable for construction applications. The process typically involves initial coarse crushing, followed by fine grinding to produce uniform particles. Modern granite grinding mills are designed to handle high hardness materials, maintain consistent product quality, and minimize maintenance costs.

Shanghai Zenith Machinery Co., Ltd. specializes in designing and manufacturing industrial grinding mills optimized for mineral processing, especially materials like granite. Our solutions focus on high reliability, low operating costs, and environmental sustainability. Among our wide range of equipment, the MTW Trapezium Grinding Mill and the LM Vertical Grinding Mill are two ideal choices for processing granite aggregates at 10–20 TPH capacity levels.

The MTW Trapezium Grinding Mill is an advanced grinding system integrating the latest European powder milling technology. It offers a combination of crushing, drying, grinding, classifying, and conveying in one compact design. The MTW series is known for its high efficiency, energy-saving features, and superior product fineness.

For granite grinding, the MTW138Z or MTW175G models are especially suited to achieve the desired 10–20 TPH output range, making them ideal for mid-sized aggregate production facilities in Australia.

| Model | Max. Feed Size (mm) | Final size (mm) | Capacity (t/h) | Main motor (kW) | Fan motor (kW) |

|---|---|---|---|---|---|

| MTW138Z | <35 | 1.6–0.045 | 6–17 | 90 | 110 |

| MTW175G | <40 | 1.6–0.045 | 9.5–25 | 160 | 200 |

The MTW Trapezium Mill provides excellent powder uniformity, reduced vibration during grinding, and enhanced durability — crucial for prolonged operation on abrasive granite materials. It is particularly suitable for construction projects requiring fine aggregate production within strict tolerances. The advanced dust collection system also meets Australia’s stringent environmental protection standards.

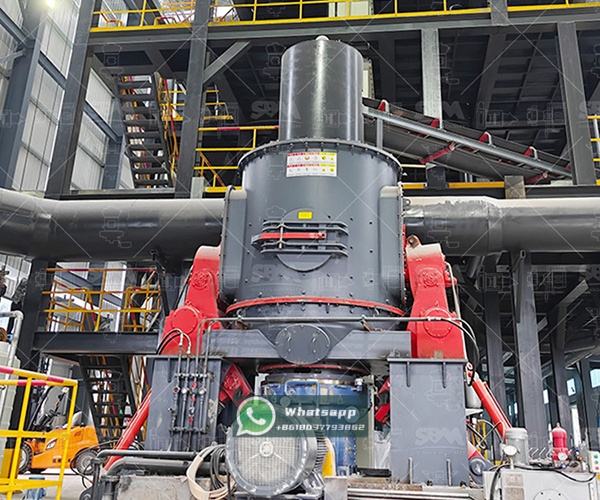

For larger-scale granite aggregate plants targeting stable 10–20 TPH throughput, the LM Vertical Grinding Mill stands out as a highly efficient, multi-functional choice. It combines crushing, grinding, drying, and powder selection into one system, minimizing energy consumption and plant footprint. The vertical structure allows for consistent material flow and better control over final product fineness.

| Model | Plate Diameter (mm) | Capacity (t/h) | Output Fineness (μm) | Max Feed Size (mm) | Main Motor (kW) |

|---|---|---|---|---|---|

| LM130K | 1300 | 10–28 | 170–40 | <38 | 200 |

| LM190K | 1900 | 23–68 | 170–40 | <45 | 500 |

The LM130K model, in particular, fits well into the 10–20 TPH range and is suitable for medium-sized construction aggregate plants. Its automation features and sealed design contribute to safety, reduced dust emission, and lower maintenance frequency. The vertical grinding configuration significantly enhances material retention and grinding precision, ensuring consistent particle distribution for high-quality construction aggregates.

Australia’s infrastructure growth is driven by highway construction, large-scale housing projects, and mineral export-related facilities. High-quality aggregates are vital to these sectors. Granite-derived fine aggregates produced with Zenith grinding systems are ideal for applications such as:

By integrating Zenith’s grinding mills into Australian aggregate production lines, companies can achieve reliable 10–20 TPH continuous production while maintaining energy efficiency and compliance with national environmental standards.

Shanghai Zenith Machinery Co., Ltd. is a globally recognized manufacturer specializing in research, development, and production of industrial powder grinding equipment. Our products embody precision engineering, long service life, and flexibility for a wide range of materials. The company’s strong technical expertise and post-sales support make Zenith the preferred partner for many construction and mining operations worldwide.

Key advantages include:

For 10–20 TPH granite aggregate production in Australia, the recommended equipment setup would combine the strengths of both the MTW Trapezium Grinding Mill and the LM Vertical Grinding Mill depending on the specific plant design. The MTW series is ideal for fine powder preparation, while the LM series delivers greater throughput and drying capacity, suitable for aggregates with variable moisture content.

These two systems can also be integrated with auxiliary devices like classifiers, conveyors, and dust collectors to create a fully automated production line meeting the highest standards of quality and efficiency.

Australia’s construction sector demands precision, consistency, and sustainability—standards that modern granite grinding systems must meet. With the MTW Trapezium Grinding Mill and LM Vertical Grinding Mill from Shanghai Zenith Machinery Co., Ltd., producers can achieve reliable 10–20 TPH production with unmatched efficiency and environmental compliance.

As infrastructure development continues across the Australian continent, the combination of advanced grinding technology and robust engineering from Zenith will continue to play a vital role in ensuring the consistent supply of high-quality construction aggregates derived from granite.

Contact Shanghai Zenith Machinery Co., Ltd. today to learn how our grinding solutions can optimize your aggregate production in Australia.