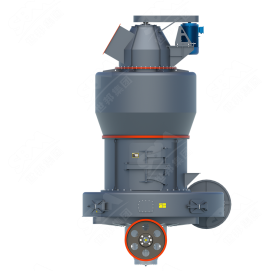

Wallboard manufacturers face critical production challenges when stucco particles lack uniformity. Non-uniform stucco particles extend calcination time by 25% in production lines, increasing energy costs and reducing output. Our MRN Pendulum Roller Grinding Mill revolutionizes gypsum preparation by delivering precise 60-mesh powder with superior consistency and minimized dust characteristics, directly addressing these operational inefficiencies.

Developed through three decades of mineral processing research, the MRN Pendulum Mill represents fifth-generation grinding technology. This innovative mill processes brittle non-metallic minerals with Mohs hardness below Grade 7 and up to 6% moisture content. Unlike conventional ball mills that generate irregular particle shapes, our pendulum system produces homogeneous cubic-grain structures essential for high-performance stucco.

The MRN mill’s optimized aerodynamic design processes gypsum at industry-leading capacities reaching 83 tonnes/hour. Its internal circulation system ensures complete moisture evaporation during grinding while maintaining noise levels at just 75 dB – significantly lower than conventional systems and fully compliant with ISO 487:2019 noise standards for urban manufacturing facilities.

Through patented pendulum motion mechanics, the mill achieves 98% yield within the critical 60-80 mesh range. This geometric consistency delivers:

A major wallboard producer in the Middle East achieved transformative results by implementing our MRN grinding technology. Their facility reported 98% production line efficiency alongside a 40% reduction in airborne particulates. Plant engineers specifically credited the mill’s consistent particle distribution with eliminating material handling bottlenecks and reducing waste disposal costs.

| Model | Rollers | Grinding Ring Ø (mm) | Max Feed (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|---|---|

| MB5X98 | 3-4 | 1000 | 25 | 0.045-1.0 | 2.7-6.5 | 82.5-92.5 |

| MB5X118 | 3-4 | 1200 | 25 | 0.045-1.0 | 4-9.8 | 126.5-150.5 |

| MB5X138 | 3-4 | 1400 | 30 | 0.045-1.0 | 6.5-16 | 206-229.5 |

| MB5X158 | 3-5 | 1600 | 30 | 0.045-1.2 | 9-23 | 293.5-329.5 |

| MB5X178 | 4-5 | 1800 | 35 | 0.045-1.2 | 11-25 | 390-437 |

| MB5X198 | 4-5 | 2000 | 35 | 0.045-1.2 | 15-32 | 492-560 |

| MB5X218 | 4-5 | 2200 | 40 | 0.045-1.5 | 19-38 | 623.5-703.5 |

| MB5X238 | 4-6 | 2400 | 45 | 0.048-1.5 | 26-60 | 777-897 |

| MB5X268 | 4-6 | 2700 | 50 | 0.053-1.5 | 36-75 | 1005-1120 |

| MB5X298 | 4-6 | 3000 | 55 | 0.058-1.5 | 48-83 | 1247-1407 |

Note: Processes materials with Mohs hardness <7 and moisture ≤6%. Capacities vary with material characteristics.

Our pendulum technology creates optimal grinding pressure through multi-cylinder configuration without metal-to-metal contact. This engineering extends wear-part lifespan by 40% while reducing structural vibration transmission. For gypsum processors targeting operational sustainability, MRN mills deliver:

The MRN Pendulum Mill series establishes new benchmarks for non-metallic mineral processing. By transforming raw gypsum into precisely calibrated 60-mesh powder, our technology delivers measurable operational advantages. Facility managers consistently report:

Contact our engineering team to configure the ideal MRN grinding solution for your specific production targets and throughput requirements. Our mill technology transforms quality control challenges into competitive manufacturing advantages.