The United Arab Emirates’ construction and industrial coatings sector is a dynamic and demanding market. A key component in high-performance paints is the filler material, which influences properties like opacity, durability, sheen control, and corrosion resistance. Phosphate rock, with its inherent chemical stability, whiteness potential, and reinforcing properties, presents an excellent raw material for premium paint fillers. However, its value is unlocked only through ultra-fine grinding to a consistent, high fineness such as 1000 mesh (approximately 13-15 microns). This process demands specialized grinding technology capable of delivering precise particle size distribution, high throughput, and energy efficiency in challenging environments.

Phosphate rock is a medium-hardness mineral. Transforming it into a uniform 1000-mesh powder suitable for paint filler applications involves significant technical hurdles. Conventional grinding mills often struggle with energy inefficiency, excessive heat generation (which can degrade material properties), and inadequate classification systems, leading to broad particle size distributions. The goal is not merely to achieve fineness but to produce a powder with a narrow, controlled size range to ensure optimal dispersion, gloss, and barrier properties in the final paint formulation. Furthermore, operational factors like dust control, maintenance frequency, and footprint are critical considerations for plants in the UAE.

Shanghai Zenith Machinery Co., Ltd. is an excellent manufacturer of ore grinding equipment in China and has made great achievements in the field of ultra-fine powder grinding. We are specialized in the research, development, and production of industrial powder grinding equipment and other related devices. With decades of experience and a global installation base, Zenith understands the precise requirements for processing minerals like phosphate rock for niche applications such as paint fillers. Our engineering philosophy centers on creating robust, intelligent, and efficient systems that deliver consistent product quality.

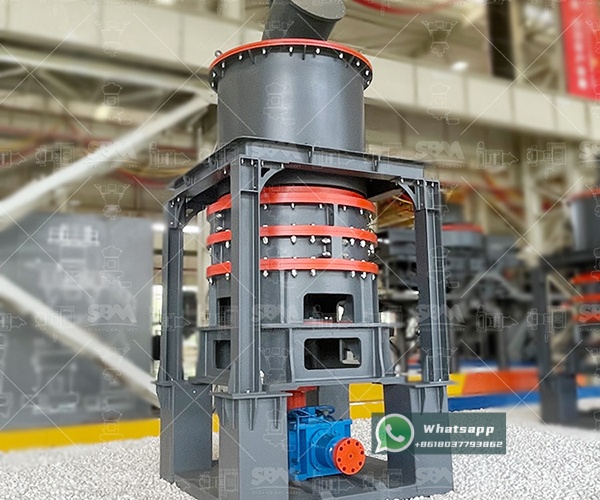

For the specific application of grinding phosphate rock to 1000 mesh for paint fillers, two of our advanced mills stand out: the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill. The XZM series is a classic and highly reliable choice for superfine powder production, while the LUM represents the pinnacle of vertical grinding technology with integrated drying and classifying.

The XZM Ultrafine Grinding Mill is widely used for superfine powder production. Its design is particularly suitable for grinding soft to medium-hard materials with moisture content below 6%. It achieves an output fineness ranging from 325 to 2500 mesh, making the 1000-mesh target well within its operational range. The mill features a high-efficiency classifier that ensures a sharp particle cut and a stable top size, which is crucial for paint filler performance.

| Model | Working Diameter (mm) | Max Feed Size (mm) | Final Size (Mesh) | Output (kg/h) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325-2500 | 500-4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325-2500 | 5000-25000 | 315 |

For a medium-scale paint filler production line in the UAE, the XZM221 model offers an ideal balance of capability and cost-effectiveness, reliably producing 1000-mesh phosphate rock powder.

For clients seeking the most advanced, energy-efficient, and compact solution, the LUM Ultrafine Vertical Mill is highly recommended. It integrates grinding, drying, classifying, and transportation into a single unit. Its unique roller and grinding plate design, coupled with an advanced forced turbine classifier, allows for precise control over the final product’s particle size distribution. The intelligent control system simplifies operation and maintenance, a significant advantage for continuous industrial production.

| Model | Main Machine Power (kW) | Capacity (t/h) | Size Distribution D97 (μm) |

|---|---|---|---|

| LUM1125 | 160-180 | 1.2-9.5 | 5-30 (approx. 600-2500 mesh) |

| LUM1436 | 250-280 | 1.8-14 | 5-30 |

The LUM series excels in producing powders with a high content of end-fines and exceptional uniformity, directly translating to superior quality in the final paint filler. Its vertical structure also results in a significantly smaller footprint.

Selecting the right equipment partner is crucial. Zenith provides more than just a machine; we offer a complete solution.

The production of high-grade paint filler from phosphate rock in the UAE is a technically sophisticated process that hinges on achieving consistent ultra-fine grinding at 1000 mesh. Shanghai Zenith Machinery’s advanced grinding mills, particularly the XZM Ultrafine Grinding Mill and the LUM Ultrafine Vertical Mill, are engineered to meet this challenge head-on. They deliver the precise particle size control, operational efficiency, and reliability required to produce a filler that enhances paint performance. By partnering with Zenith, UAE-based manufacturers can secure a competitive edge, transforming local phosphate resources into a high-value additive for the regional and global coatings industry.