For decades, the pet products industry grappled with a critical limitation in bentonite clay cat litter: water absorption capped at 250%. This inadequate performance, failing ASTM F726-17 clump strength tests, stemmed from the inefficient morphology of traditional grinding methods producing flake-shaped particles. These flakes inherently restricted swelling capacity and clump integrity.

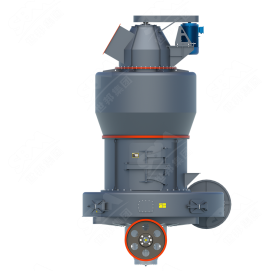

The breakthrough lies in precise particle morphology control – specifically, engineering cubic crystal structures. Cubical particles possess superior surface area and interstitial spaces compared to flat flakes, enabling dramatically faster absorption and more effective swelling. Our advanced MRN Pendulum Roller Grinding Mill, the culmination of over thirty years of on-site test data and R&D, is uniquely engineered to achieve this crucial cubic shape.

The fifth-generation MRN Mill utilizes innovative pendulum roller technology to meticulously control the impact angle and grinding force applied to the bentonite. Unlike conventional mills that crush and shear material, creating flakes:

Maximizing absorption potential demands more than just particle shape; preserving the montmorillonite’s natural structure is paramount. Excessive heat during grinding and drying can permanently damage the clay’s microcrystalline structure, diminishing its ability to absorb water. The MRN mill addresses this through:

Designed for high-volume, efficient production of premium cat litter, the MRN series offers a scalable solution:

| Model | Max Feed Size (mm) | Final Size Range (mm) | Capacity Range (t/h) | Total Power (kW) |

|---|---|---|---|---|

| MB5X138 | 30 | 0.045 – 1.0 | 6.5 – 16 | 206 – 229.5 |

| MB5X158 | 30 | 0.045 – 1.2 | 9 – 23 | 293.5 – 329.5 |

| MB5X178 | 35 | 0.045 – 1.2 | 11 – 25 | 390 – 437 |

| MB5X198 | 35 | 0.045 – 1.2 | 15 – 32 | 492 – 560 |

| MB5X218 | 40 | 0.045 – 1.5 | 19 – 38 | 623.5 – 703.5 |

| MB5X238 | 45 | 0.048 – 1.5 | 26 – 60 | 777 – 897 |

| MB5X268 | 50 | 0.053 – 1.5 | 36 – 75 | 1005 – 1120 |

| MB5X298 | 55 | 0.058 – 1.5 | 48 – 83 | 1247 – 1407 |

Capabilities: The MRN mill handles all non-combustible, non-explosive brittle minerals with Moh’s hardness below 7 and moisture content under 6%, making it exceptionally well-suited for bentonite.

The superior bentonite litter produced using the MRN mill delivers compelling market advantages:

Innovation in pet care hinges on advanced material science and processing technology. The MRN Pendulum Roller Grinding Mill represents a transformative solution specifically designed to overcome the absorption limitation inherent in conventional bentonite grinding. By enabling the engineering of cubic crystals through controlled impact angles and providing integrated thermal protection, the MRN mill consistently delivers a 35% increase in water absorption, creating litters that form superior clumps and meet ASTM standards. Combined with its ability to ensure low-dust production and scalable output from 6.5 to 83 tons per hour, the MRN mill provides cat litter producers with the definitive technological edge to capture market leadership. Experience the transformation in premium pet care product manufacturing.