In the metallurgy industry, calcium carbonate serves as a crucial fluxing agent, aiding in the removal of impurities and improving metal quality during smelting and refining processes. High-quality flux materials contribute not only to better metallurgical performance but also to energy efficiency and cost-effectiveness. In Australia, where the mining and metallurgy sectors are among the most advanced globally, the demand for stable, efficient grinding systems for calcium carbonate (CaCO₃) has grown substantially. To meet these requirements, Shanghai Zenith Machinery Co., Ltd.—a leading Chinese manufacturer of ore grinding equipment—provides advanced grinding solutions optimized for fine and ultra-fine powder processing, ideally suited for 1–3 TPH (tons per hour) production capacity.

Shanghai Zenith has accumulated comprehensive expertise in the field of ultra-fine powder grinding. Their products, such as the MTW Trapezium Grinding Mill and the XZM Ultrafine Grinding Mill, are widely adopted in multiple industries ranging from metallurgy to mining and chemical production, ensuring precise particle size control and outstanding durability.

Calcium carbonate is extensively used in metallurgical processes as a flux for refining iron, copper, and other non-ferrous metals. Its purpose is to combine with silica, aluminum oxide, and other impurities to form a liquid slag, which can easily be separated from the metal phase. The fine grinding of CaCO₃ is therefore essential, as smaller particle sizes increase reaction rates and enhance slag fluidity. The target fineness for flux-grade calcium carbonate typically ranges from 45 μm to under 10 μm, depending on the metal grade requirements and process specifications.

Producing consistent, fine particles requires stable mechanical performance, controlled grinding parameters, and efficient classification. For operations in Australia that require medium-capacity production (1–3 TPH), selecting the right grinding mill is crucial for achieving both cost and quality targets.

Australia’s metallurgical enterprises expect high efficiency, environmental compliance, and reliable mill performance under variable mineral characteristics. Essential requirements for CaCO₃ grinding mills include:

Shanghai Zenith’s grinding mills are designed with these performance principles in mind. Each model incorporates reliable mechanical structure, sealed operation for pollution control, and adaptive systems for stable material feeding and discharge.

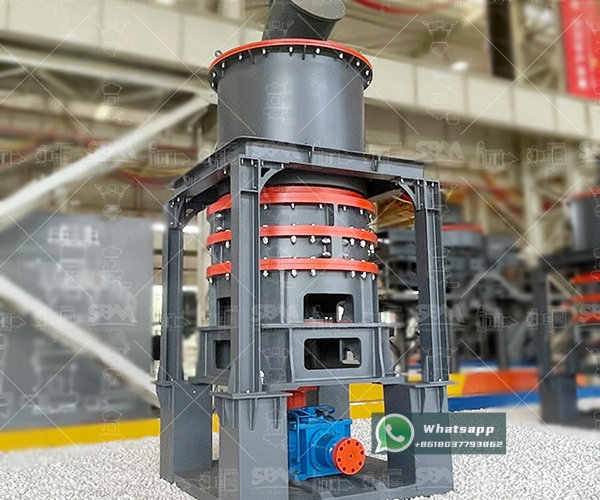

For producing calcium carbonate flux within the 1–3 TPH capacity range, the MTW Trapezium Grinding Mill from Shanghai Zenith is highly recommended. This model integrates advanced European design principles, featuring bevel gear transmission, internal thin oil lubrication system, and arc-shaped air channels for enhanced material separation efficiency.

The MTW series is particularly suitable for processing non-metallic minerals like calcium carbonate, limestone, barite, and dolomite. The machine ensures stable particle distribution, extended component lifespan, and low operational noise—all of which are beneficial in Australian metallurgical operations that emphasize safety and sustainability. Below is a summary of its key technical parameters:

| Model | Max. Feed Size (mm) | Final Size (mm) | Capacity (t/h) | Main Motor (kW) | Fan Motor (kW) |

|---|---|---|---|---|---|

| MTW110 | <30 | 1.6–0.045 | 3–9 | 55 | 55 |

| MTW110Z | <30 | 1.6–0.045 | 3–10 | 55 | 55 |

The MTW110 and MTW110Z are excellent models for small-scale grinding systems that require precise calcium carbonate powder for metallurgy flux. Their user-friendly maintenance and robust design make them ideal choices for operations in remote Australian mining regions.

For finer powder requirements, the XZM Ultrafine Grinding Mill is another recommended option. The XZM series achieves ultra-fine output from 325 to 2500 mesh and offers exceptional performance for CaCO₃ grinding when the metallurgical process needs lower particle size thresholds. The mill operates with low energy consumption, ensuring economical operation for 1–3 TPH output while maintaining strict control over particle uniformity.

This mill’s compact design and advanced classifier system make it particularly useful for calcium carbonate flux preparation in facilities where space and energy optimization are priorities. Its ability to handle raw materials with moisture below 6% ensures consistent production under Australia’s varied climate conditions.

| Model | Working Diameter (mm) | Max Feed Size (mm) | Final Size (mesh) | Output (kg/h) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325–2500 | 500–4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325–2500 | 5000–25000 | 315 |

Deploying a calcium carbonate grinding system in Australian metallurgical facilities involves several consideration factors—raw material source proximity, moisture content, transportation logistics, and environmental controls. Zenith’s engineering team offers complete technical support, from on-site equipment layout planning to commissioning and training. For metallurgy flux production, the company typically integrates the mill with dust collectors, pneumatic conveying lines, and storage silos, forming a complete, automated grinding system.

In several case studies, the adoption of Zenith’s MTW and XZM series mills for CaCO₃ flux production has demonstrated measurable improvements in metallurgical performance. Operators report enhanced slag fluidity, lower energy use in smelting, and improved metal recovery rates. For instance, one mid-sized Australian copper smelter saw a 15% reduction in flux consumption and improved furnace efficiency after upgrading to MTW110 grinding technology. Another operation utilizing the XZM221 achieved flux fineness below 10 μm consistently, ensuring superior control over refining reactions.

For the production of high-quality calcium carbonate flux in Australia’s metallurgical industry, Shanghai Zenith Machinery Co., Ltd. offers reliable grinding solutions that deliver both performance and sustainability. The MTW Trapezium Grinding Mill provides precise output for moderate fineness, while the XZM Ultrafine Grinding Mill ensures ultra-fine powder production for high-end metallurgical processes. Together, these mills form a proven choice for metallurgical facilities targeting 1–3 TPH calcium carbonate grinding capacity. By leveraging Zenith’s advanced grinding technology, Australian plants can achieve consistent flux quality, reduced operational costs, and a higher level of environmental compliance.

Shanghai Zenith Machinery Co., Ltd. continues to lead the industry through innovation, manufacturing excellence, and customer-oriented engineering support— solidifying its position as a global partner in the metallurgical and mining sectors.