Diatomite, also known as diatomaceous earth, is a naturally occurring sedimentary rock composed of fossilized remains of diatoms, a type of algae characterized by their unique silica cell walls. Due to its high porosity, excellent filtration properties, and chemical stability, diatomite has become a preferred material in the water treatment industry. In Qatar, where sustainable water purification and desalination systems play a critical role in domestic and industrial uses, the demand for fine diatomite powder—especially around 325 mesh fineness—continues to grow dramatically.

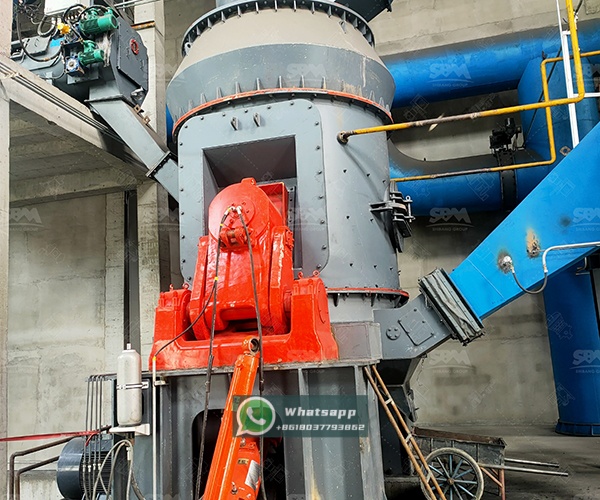

To produce high-quality 325 mesh diatomite powder for water treatment applications, advanced grinding technology is necessary. Shanghai Zenith Machinery Co., Ltd., a leading Chinese manufacturer of industrial grinding equipment, provides state-of-the-art solutions for fine and ultra-fine powder production. Among its product range, the MTW Trapezium Grinding Mill and the XZM Ultrafine Grinding Mill stand out as reliable machines ideally suited for diatomite processing at industrial scale.

In Qatar, fresh water resources are scarce, and desalinated water is the primary source for domestic supply. However, after desalination or wastewater treatment, additional purification stages are often required to remove residual particles, bacteria, and organic compounds. It is in this context that diatomite proves particularly valuable. Its highly porous and inert silica structure makes it an outstanding filtration medium, removing impurities and improving water clarity without introducing contaminants.

To ensure high filtration efficiency, the diatomite must be ground to a uniform fine size. Typically, 325 mesh (about 45 microns) is the standard for water treatment-grade diatomite powder. Achieving this level of precision and consistency requires advanced milling technology that can handle both soft and brittle materials while maintaining purity and minimizing contamination.

Diatomite’s physical characteristics—lightweight, porous, and brittle—make it a unique but challenging material to grind. Conventional mills often generate too much heat or cause particle agglomeration, leading to product inconsistency and energy waste. Moreover, in large-scale water treatment material production, stability and efficiency are key performance factors. The grinding process must ensure a narrow particle size distribution, low energy consumption, and minimal material loss.

This is where the advanced grinding technology from Shanghai Zenith Machinery Co., Ltd. makes a remarkable difference. The company’s grinding systems integrate precision engineering, automatic control, and dust-proof designs to guarantee high processing quality, even under continuous operation.

Shanghai Zenith Machinery Co., Ltd. offers multiple grinding solutions that can consistently produce diatomite with a particle size around 325 mesh. Among its broad portfolio of milling equipment, the MTW Trapezium Grinding Mill and XZM Ultrafine Grinding Mill are two highly recommended options for water treatment applications in Qatar.

The MTW series is known for its modern design, integrated analyzer, and high-efficiency blower that enables precise powder classification. It is ideal for processing non-metallic minerals such as diatomite, limestone, and gypsum. The unique trapezium working surface and advanced multi-stage sealing system ensure stable and environmentally friendly operation. For water treatment-grade diatomite, the MTW175G and MTW215G models provide excellent performance and production efficiency.

| Model | Max. Feed Size (mm) | Final Size (mm) | Capacity (t/h) | Main Motor (kW) | Fan Motor (kW) |

|---|---|---|---|---|---|

| MTW175G | <40 | 1.6–0.045 | 9.5–25 | 160 | 200 |

| MTW215G | <50 | 1.6–0.045 | 15–45 | 280 | 315 |

The final powder is uniform, with high surface activity, making it especially suitable for filtration-grade diatomite production. The energy-efficient design also ensures low operational cost and minimal environmental footprint—two aspects critical for sustainable operations in Qatar.

For clients seeking even finer diatomite powder, Shanghai Zenith’s XZM Ultrafine Grinding Mill is the ideal choice. This mill can produce powders ranging from 325 to 2500 mesh, giving manufacturers great flexibility in adapting their product specifications. The XZM series employs multiple-layer rollers and a high-efficiency classifier, ensuring consistent fineness and lower vibration. Its closed grinding system design effectively prevents dust emission and maintains environmental safety standards.

| Model | Working Diameter (mm) | Max Feed Size (mm) | Final Size (mesh) | Output (kg/h) | Main Motor Power (kW) |

|---|---|---|---|---|---|

| XZM221 | Φ800 | ≤20 | 325–2500 | 500–4500 | 75 |

| XZM268 | Φ1680 | ≤20 | 325–2500 | 5000–25000 | 315 |

The XZM Ultrafine Grinding Mill is particularly recommended when ultra-fine diatomite is needed for premium filtration media or for specialized industrial uses such as pharmaceutical or food-grade filtration systems in Qatar’s diverse market.

Shanghai Zenith Machinery’s grinding mills bring several clear advantages to diatomite producers and water treatment equipment manufacturers in Qatar:

Qatar’s continued investment in water infrastructure and environmental technology makes it a promising market for high-quality diatomite-based filtration media. From municipal water treatment plants to industrial cooling systems and even beverage production facilities, 325 mesh diatomite plays a critical role in achieving high water purity standards. By integrating Shanghai Zenith’s MTW or XZM grinding mills into production lines, Qatari manufacturers can improve processing efficiency, reduce costs, and ensure stable supply of fine diatomite powders suitable for various filtration systems.

As Qatar advances toward its vision of sustainable infrastructure and water management, demand for quality water treatment materials like diatomite continues to rise. Producing consistent 325 mesh diatomite requires reliable and sophisticated grinding technology. Shanghai Zenith Machinery Co., Ltd., with its strong engineering background, advanced manufacturing capacity, and a comprehensive portfolio of grinding solutions, stands ready to support the Qatari market with tailored systems for superior diatomite powder production. Whether through the robust MTW Trapezium Grinding Mill or the precision-driven XZM Ultrafine Grinding Mill, Zenith ensures exceptional grinding performance that meets the highest industrial standards.

For more details about customized solutions or consultation on diatomite grinding for water treatment in Qatar, please contact Shanghai Zenith Machinery Co., Ltd.—your trusted partner in advanced powder processing technology.